An easy step-by-step guide to Six Sigma in 2025

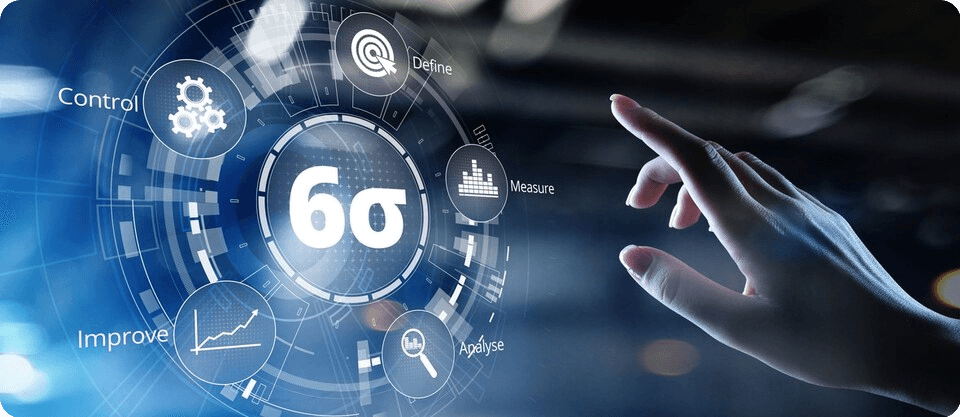

Six Sigma is often used in project management to improve processes through the use of a set of techniques and tools. It is a data driven and statistical technique aimed at eliminating product defects rather than identifying and documenting defects.

The Six Sigma methodology takes into account stakeholder requirements and ensures an improvement in products, services and processes across an organisation. The benefits of this methodology also include greater stakeholder satisfaction and a reduction in costs, which results in increased realised profits and an improvement in competitive advantage.

With that said, here are some useful steps for organisations and project teams to adopt the Six Sigma methodology.

1. Develop a problem statement

Problem statements are a great way to document the immediate problem that needs to be addressed. Before developing any type of solution it is important to have an adequate understanding of the causes of a problem and the consequences of the problem as it exists. For example, an organisation whose IT infrastructure is based on legacy systems might be plagued with inefficiencies that cause a loss in productivity across several departments and as a result erodes the organisation’s competitive advantage. Here the problem is simply identified and isolated without putting forward a solution prematurely.

2. Identify objectives

Once the problem has been identified the next logical step is to envision and document the ideal end-result after the problem has been addressed. One way to conceptualise this is by comparing “what is vs what should be”. That is to say that after the solution has been implemented, the desired outcomes should be a vast improvement over the current state of things. Building on our previous example, if the legacy systems of an organisation have become obsolete and unable to keep up with current business processes, those systems will have to be upgraded to meet organisational goals. By this step both the problem is identified and a solution is proposed.

3. Analyse current set of processes

During this phase data collection is performed to analyse the performance and issues of the existing process and infrastructure. The data gathered is used to serve as a process map to further document existing issues while taking into account the requirements of existing stakeholders. While the analysis is performed it is good practice to update the project charter if one exists. This allows deliverables to be drafted which will inform how the solution is to be implemented.

4. Roll out process improvements

With the problem being identified, the solution being formulated and the analysis of existing processes completed it is time to implement the solution. This is a step that happens gradually instead of being implemented all at once. It is also worth noting that it is a step that occurs throughout a number of iterations as feedback is gathered from stakeholders. The feedback is taken into account as the incremental improvements are made. For example, an organisation that requires new processes to be implemented and legacy systems to be updated are very unlikely to shut all systems down and roll out its new solution. This would bring the entire organisation to a standstill causing a massive loss in productivity. Instead it would be more advisable to run the legacy system and processes in parallel with the new solution as it is gradually rolled out. This ensures that the organisation is able to remain productive and operational while the solution being gradually implemented eventually cannibalises the legacy system. The goal here is to prevent defects from occurring as the solution is rolled out.

5. Document and monitor new process

Once the solution and new processes have been implemented it is imperative to monitor the realised gains should any exist. During this step the new processes and solutions should be evaluated regularly to outline the improved changes and how they impact all stakeholders and the overall organisation’s performance. That is not to say that additional changes cannot or will not be made further down the line of the project life-cycle. If anything, the new process and solution can be refined as the implementation gradually settles throughout the organisation. This enables the organisation to maximise the return on investment which could further benefit all stakeholders, improve competitive advantage, increase profits and reduce organisational operation costs.

Despite this methodology being called the Six Sigma, there are only five steps to the process. Do you want to learn more about project management? Check out our Project Management Course.